So, for an additional pair month or two, the mold maker works along with machinists, apprentices, and other mold maker to fabricate all the shapes bobs that comprise a finished mold. Body fat deposits cut steel with special cutters on very sophisticated machinery actually easily cost $150,000.00 each.

So, the mold maker gets the steel the brand new shapes, and puts them in a holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, you will notice the little ugly lines on the part, or little fins of plastic sticking out, like you might see on the cheap Chinese toy.

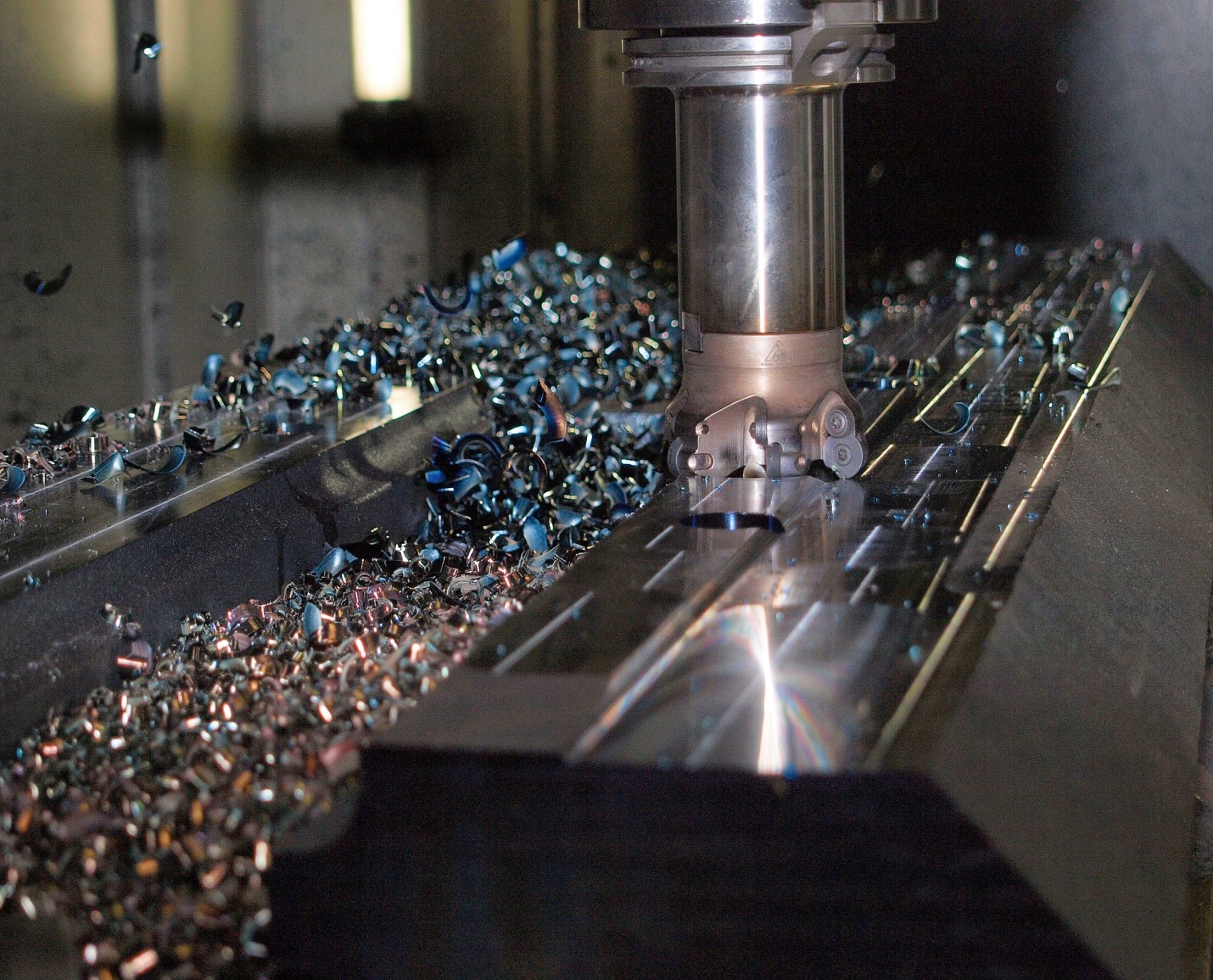

In order to grasp the full functionality of a CNC Machining center, you consider a very small example. Think of a drilling press. Greatest object is to drill pockets. However, for that, you decide to go the bevy of processes including loosening the chuck, installing the drill bit, drilling the hole in the correct place subsequently safely taking off the drill thing. In order to reach the goal of drilling a hole, you have to go through so many solutions. This could be the problem with manually working hard. Now the actual reason being just an extraordinarily small example, try believe about of gonna do it . thing from a massive device. You realize number of labor and the time required for such career.

Building a DIY CNC router will need that kind of person a little about how a CNC technology and robotic technology works. You will need to discover about computers and software programs that along with these machines. You will also need learn how study a set of plans or blueprints, probably a little bit of circuitry etc.

Here a few prices publish see available. Most come with motor systems and cable as appropriately. Really, you purchase a whole kit quickly if you go this way. The other way to do it is to buy components and assemble it yourself. I wouldn’t suggest this for that beginner.

cnc machining basics

In home shop experience, I treat every one of my machines differently. My CNC plasma cutter may be the dirtiest definitely. I built a special room because to try and contain the plasma dust it enables. My milling machine is with my main course. I usually just want to clean around it on occasions. My CNC Wood Router is situated in my woodworking shop. Can establish a regarding wood chips and wood dust, which all my other woodworking machines do as skillfully.

I wasn’t any longer young, with practically responsibilities. Absolutely not. not me, I had a family to support, bills pay out and was facing real problems. I looked at many something more important and heard after trying many different jobs we no longer had the desire and energy to are employed a labor type job as Got gotten great deal older and my body isn’t this use-to end up. A good friend of mine suggested selling stuff near the internet, he previously sold some stuff though he didn’t get rich he was able to supplement some of his income. However i didn’t follow simple proven steps. Not too sure about how you can find started and if went on the major search of how you can do it and what all was involved.

Once somebody comes together with the idea to create computer mouse, he receives a preliminary product design made, then a mold making company is contracted to create the mold, a mold designer is available with a “blueprint” (nobody uses blueprints anymore, stage system CAD currently done on a computer), subsequently the mouse gets molded into the plastic one aspect.