In the fast-paced world of material handling, maximizing efficiency and productivity is crucial for any business. One essential tool that can greatly enhance the lifting capabilities of your forklifts is the use of fork lift extensions. These versatile attachments allow you to handle larger and heavier loads with ease, significantly expanding the range of tasks your forklift can perform. Whether you are in warehousing, construction, or logistics, understanding how to effectively utilize fork lift extensions can lead to smoother operations and improved workflow.

Forklift Attatchments

Fork lift extensions come in various sizes and styles, designed to accommodate different types of loads and operational needs. By extending the reach of your forklift’s forks, you can safely handle items that might otherwise be difficult to transport. This not only enhances the performance of your equipment but also contributes to safer working conditions by reducing the risk of overloading or improper handling. In this guide, we will explore the benefits of fork lift extensions, tips for their use, and essential considerations to keep in mind for your specific application.

Understanding Forklift Extensions

Forklift extensions are specialized accessories designed to increase the reach and lifting capacity of standard forklift forks. They are essential tools in various industries, particularly in warehousing and construction, where handling long or bulky loads is common. By providing additional length to the existing forks, these extensions allow operators to transport oversized materials safely and efficiently, reducing the need for multiple trips and increasing productivity.

When using forklift extensions, it is crucial to consider the weight limits and the stability of the loads being lifted. Extensions come in various sizes and configurations, so selecting the right type based on the specific requirements of your operations is essential. Properly fitted extensions can enhance both performance and safety when lifting heavy or awkwardly shaped items. They should be compatible with the forklift’s existing forks and adhere to manufacturer guidelines to avoid accidents.

In addition to improving reach, forklift extensions can also help in optimizing warehouse space. By allowing for the stacking of longer items, they facilitate better organization and maximize the use of vertical storage areas. This can lead to increased efficiency in inventory management and a smoother workflow in loading and unloading operations. Understanding the benefits and proper usage of forklift extensions can significantly enhance your material handling capabilities.

Types of Forklift Extensions

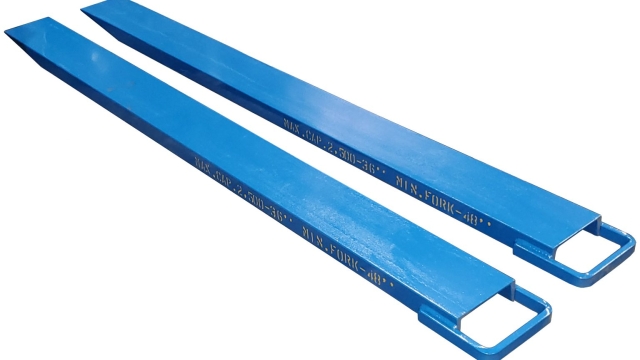

Forklift extensions come in various types that cater to different lifting needs and applications. The most common type is the standard fork lift extension, which simply adds length to the existing forks. These extensions are typically made from durable steel and are designed to fit securely over the existing forks, allowing for the transport of larger or longer loads without compromising stability. Standard extensions are easy to install and remove, making them a popular choice for warehouses that handle a variety of materials.

Another type of forklift extension is the telescopic fork lift extension. This design allows for adjustable lengths, enabling operators to extend the forks to various sizes depending on the load being handled. Telescopic extensions offer versatility and can be particularly beneficial in environments where different loads are frequently moved. By adjusting the length of the forks, operators can improve efficiency and reduce the risk of overload or improper handling.

Lastly, there are specialized fork lift extensions designed for specific types of loads or operations. For example, carpet poles or drum handlers are tailored extensions that enable the safe and effective transportation of particular items. These specialized extensions not only enhance the functionality of forklifts but also increase safety by ensuring that loads are transported in a secure manner. Choosing the right type of fork lift extension is crucial for maximizing operational efficiency and safety in any lifting environment.

Benefits of Using Forklift Extensions

One of the primary benefits of using forklift extensions is increased reach. Standard forklift forks may not accommodate oversized loads or extend into hard-to-reach areas. With extensions, operators can easily lift and transport larger items without the need for additional equipment. This capability enhances productivity and efficiency in various industries, allowing for smoother operations and reduced downtime.

Another advantage is improved safety. Using extensions designed specifically for forklifts can help prevent load tipping or shifting during transport. When loads are adequately supported and balanced, the risk of workplace accidents decreases significantly. Properly fitted extensions ensure that operators can handle bulky materials with confidence, ultimately contributing to a safer work environment for everyone involved.

Additionally, forklift extensions offer versatility. Businesses often require the lifting and transporting of various products, which can change frequently. Extensions can be quickly applied or removed, allowing operators to adapt to specific tasks without needing multiple forklifts for different jobs. This flexibility not only saves on costs associated with purchasing additional equipment but also maximizes the operational capabilities of existing forklifts.

Safety Considerations and Best Practices

When using forklift extensions, safety should always be a top priority. It is essential to ensure that the extensions are compatible with the forklift model being used. Each forklift has a specific load capacity, and using extensions can alter this capacity. Always check the manufacturer’s guidelines before attaching extensions to avoid overloading the vehicle, which can lead to accidents and equipment failure.

Proper training for operators is crucial when using forklift extensions. Operators should be educated on the specific handling techniques required when using extensions, including load balancing and maneuvering in tight spaces. It is recommended that operators perform a pre-use inspection of both the forklift and the extensions to ensure they are in good condition and free from defects. This proactive approach can help prevent incidents that may arise from equipment malfunction.

Additionally, maintaining a clear and organized work area can enhance safety when using forklift extensions. Ensure that pathways are free of obstacles and that the area is well-lit. Establish clear communication among team members, especially when operating in busy environments, to avoid collisions and ensure efficient operation. At all times, adhere to local safety regulations and guidelines to create a safe working environment for everyone involved.